Fan Mod Lid

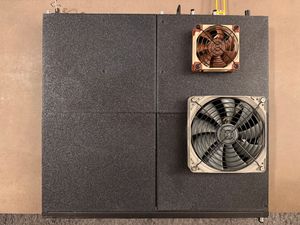

To mount bigger, quieter fans to the top of my ICX 7450, I needed to find a way to cut or otherwise create some holes in the lid, to screw the fans on the outside. I designed some 3D-printed plates for this purpose.

Drawings

This is no recipe blog: here's the good stuff up front. I've uploaded two sets of files here.

The first set, of STLs, is exactly what was printed in the photos below - they fit as shown. The panel blanks are flimsy; and the fan bay blank really should've had a tab on both sides for support. Also the fan bay blank has a cutout for the potentiometer that came with my fan controller, so if that's not what you want... sorry.

The second set of files is the source Autodesk Fusion models - but at some point after printing my own panels, I made an attempt at fixing that gap. I think I understand which dimension I got wrong, and I tried to correct it. But this version is untested. I have never printed them, nor test-fit templates on the switch. Print at your own risk.

Download the UNTESTED Fusion drawings here.

Download the printed STLs, with the gap in the middle, here.

The idea

A lot of switch fan mods posted on the forums take some sort of sheet material - acrylic, steel, the original switch lids - and cut big holes in them for fans. I have no confidence in my ability to do so neatly or without injury, nor do I have the tools. In any case, I didn't want to cut the original lids, lest this all go sideways. I wanted to be able to revert my modifications.

Others who fabricated new lids for their switches used scrap materials they had lying around, but I didn't have anything handy. I looked into buying something; the cheapest polycarbonate sheet I could buy locally would have been more than $60 (all prices CAD).

What I did have, though, was a very generous friend with a 3D printer, and just enough knowledge from my first-year CAD course to take a stab at modelling some panels & blanks. I ended up paying him $20 (and a bag of nice coffee beans) to print two sets of lids + blanks for the rear bays. (He insists this was overpayment.)

Designing the 3D-printed plates

My friend's printer had a print bed of something like 240x240mm. This was a little more than 1/4 of the area of the lid. So I designed four equally-sized plates, with screw holes where the original lid had them. Fortunately, the original lid had lots of screw holes, even in the middle of the switch. This didn't quite give me mounting posts at each corner of each plate, but it was close enough for my liking. Then I added cutouts for fans & their mounting screws.

My main challenge was getting the dimensions right. I'm not sure how someone would do this if they actually knew what they were doing. I used what I had and made it work:

- any dimension I could Google, that had a standard, I used

- countersink angles, standard screw hole sizes, etc.

- anything that was within reach of two points of my cheap digital calipers, I measured with that

- if it involved a circular feature, like the distance between screw holes, I measured it a lot and rounded to the nearest reasonable value (lol)

- as I write this I probably should've measured both between the outside and the inside of the pair of holes... wish I'd thought of it then!

- if it involved a circular feature, like the distance between screw holes, I measured it a lot and rounded to the nearest reasonable value (lol)

- anything that was out of reach of the calipers, I used the only measuring tape I had with millimeter markings, and took my best guess (lololol)

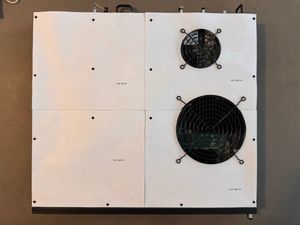

And then I printed out 1:1 drawings of the designs, and screwed the paper into the switch (also lol) to see how close I got. This was good within a millimeter or two:

I iterated a few times, and then felt confident enough to have my friend try a print.

Frankly, I'm impressed at how close I got to the correct dimensions this way. My main regret is that I got something slightly wrong relating to the overall width of the switch, or the horizontal distance between two points I used, or something, resulting in a gap of 1-2mm down the center between the left and right panels. Oh well.

My friend did the slicing and printing, so I can't speak to the choices he made there, in terms of infill, material, etc.